What Makes Quinoline Derivatives So Indispensable in Modern Chemistry?

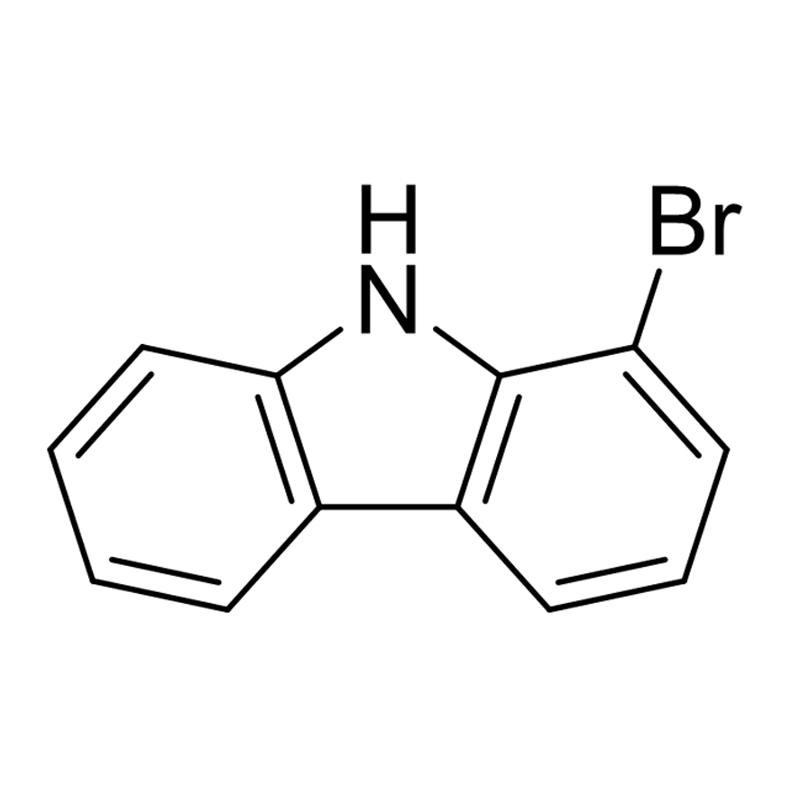

Apr 18,2025Exploring the Potential of Carbazole Derivatives: Unlocking New Horizons in Organic Chemistry

Apr 11,2025What Are Polymide Derivatives and Why Are They Essential in Modern Applications?

Apr 03,2025How Are Thiophene Derivatives Used in the Pharmaceutical Industry?

Mar 25,2025How Do Thiophene Derivatives Behave Under Nucleophilic Substitution Reactions?

Mar 20,2025The synthesis conditions have a significant impact on the yield, purity, and optoelectronic properties of carbazole derivatives. These conditions mainly include reaction temperature, choice of solvent, type and amount of catalyst, reaction time, and subsequent purification steps. Below is a detailed analysis of these influencing factors:

Reaction temperature is one of the key factors that affect the rate and equilibrium of a chemical reaction. In the synthesis of carbazole derivatives, the choice of reaction temperature directly influences the yield and purity of the product.Effect on Yield: Generally, as the reaction temperature increases, the reaction rate accelerates, and the product yield correspondingly increases. However, if the temperature exceeds a certain range, excessively high temperatures may cause the decomposition of reactants, increase in side reactions, or catalyst deactivation, thereby reducing the yield. For example, in the synthesis of chloroethyl carbazole, when the reaction temperature reaches 60°C, the yield reaches its highest (69.85%), but when the temperature continues to rise to 80°C, the yield decreases (possibly due to the partial decomposition of the phase transfer agent under strong alkaline conditions).Effect on Purity: The reaction temperature also affects the purity of the product. At high temperatures, reactants may be more prone to side reactions, generating impurities and thus reducing the purity of the product.

Choice of Solvent:Solvents play a role in dissolving reactants, promoting the reaction, and separating products in chemical reactions. Different solvents have varying effects on the synthesis of carbazole derivatives.Effect on Yield: The polarity, solubility, and stability of the solvent can affect the solubility of the reactants and the reaction rate, thereby influencing the yield. For instance, in some synthetic reactions, polar solvents like DMF or THF may be more advantageous than non-polar solvents because they can better dissolve reactants and promote the reaction. However, if the solvent undergoes undesirable reactions with the reactants or products, it may lead to a decrease in yield.Effect on Purity: The choice of solvent also affects the product separation and purification process. Using an appropriate solvent can make it easier to separate the product from the reaction mixture through methods such as crystallization or extraction, thereby improving the product's purity.

Type and Amount of Catalyst:Catalysts accelerate the reaction rate without altering the overall energy change of the reaction. Different catalysts have varying catalytic effects on the synthesis of carbazole derivatives.Effect on Yield: The type and amount of catalyst directly affect the reaction rate and yield. Choosing the appropriate catalyst can significantly increase the reaction rate and yield. For example, in the synthesis of N-butyl carbazole, the yield is highest when the molar ratio of potassium hydroxide to carbazole is 1.1. However, an excess of catalyst may also lead to an increase in side reactions or product decomposition, thereby reducing the yield.Effect on Purity: Residual catalysts can affect the purity of the product. Therefore, after the reaction, it is necessary to thoroughly remove the catalyst or convert it into a harmless substance.

Reaction Time:Reaction time is another important factor that affects the yield and purity of carbazole derivatives.Effect on Yield: Insufficient reaction time may lead to incomplete reactions, thus reducing the yield. However, excessively long reaction times may lead to an increase in side reactions or product decomposition. Therefore, the appropriate reaction time should be chosen according to specific reaction conditions to achieve the best yield.Effect on Purity: Reaction time also affects the product separation and purification process. Stopping the reaction in a timely manner after its completion and proceeding with the separation and purification of the product can enhance the product's purity.

Different synthesis conditions have a significant impact on the yield, purity, and optoelectronic properties of carbazole derivatives. In practical synthesis, it is necessary to optimize these conditions according to specific reaction parameters to achieve the best results.

Copyright © 2023 Suzhou Fenghua New Material Technology Co., Ltd. All Rights Reserved.

Custom OLED Material Intermediate Manufacturers